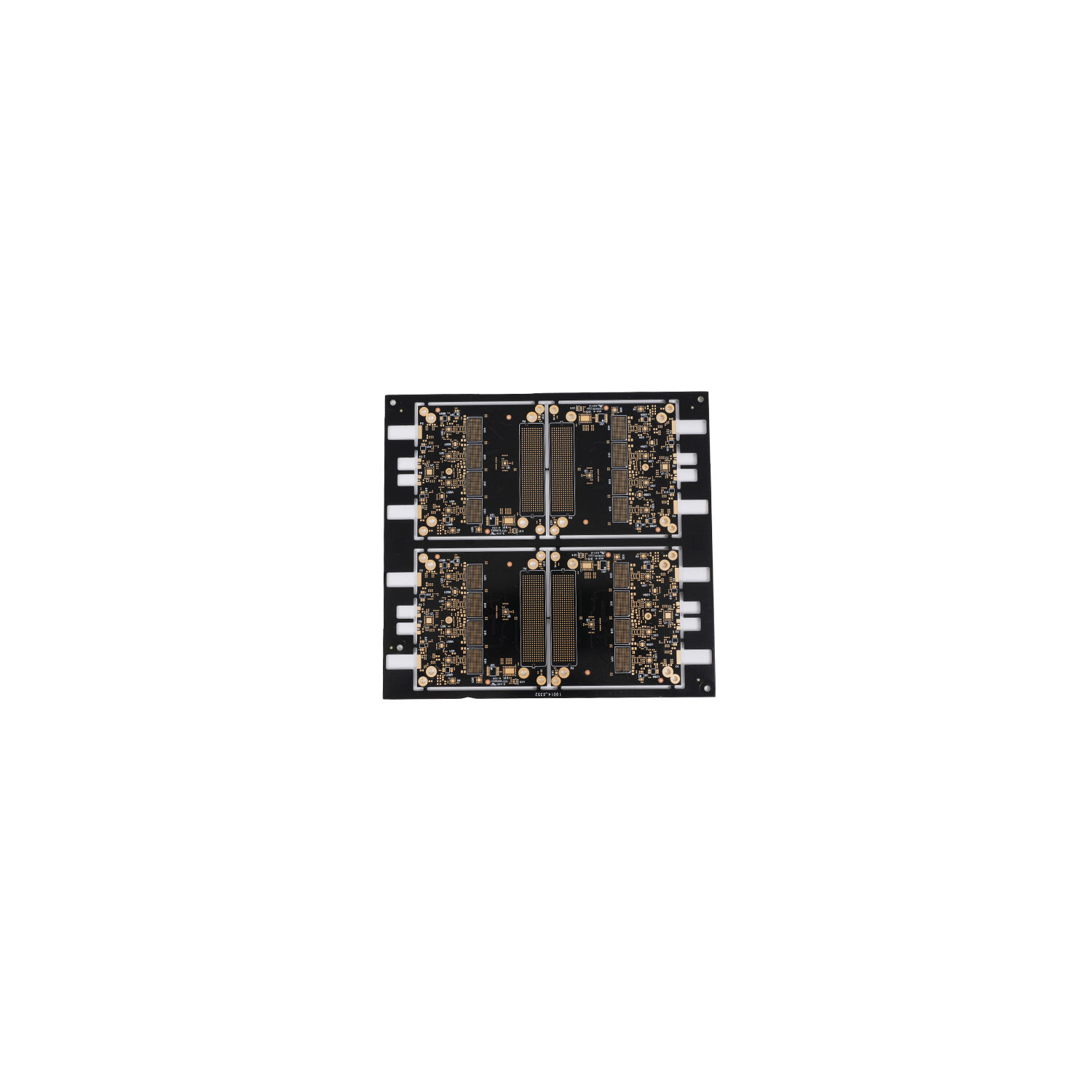

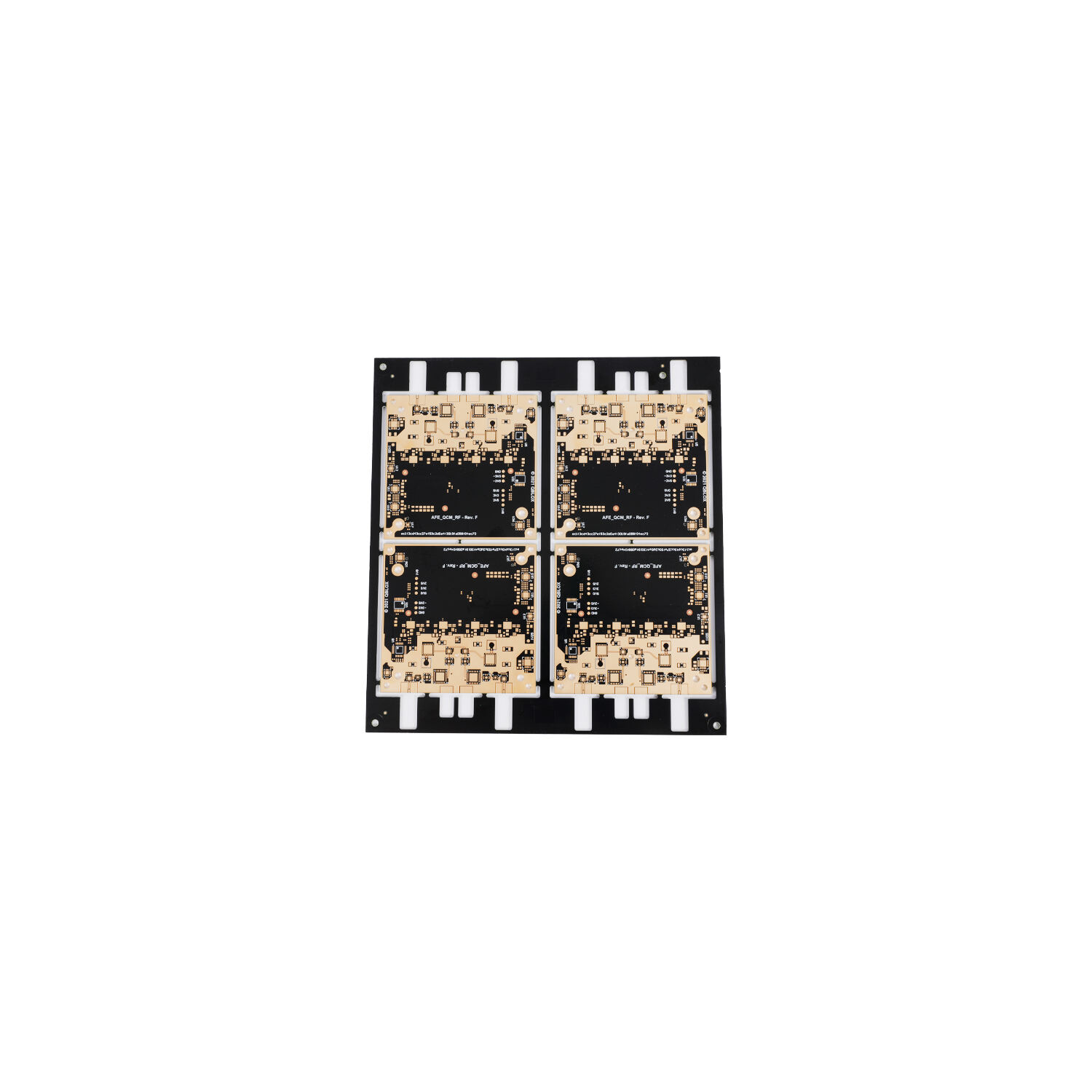

Prototype PCB assembly is a specialized service focused on transforming design concepts into functional lowvolume PCBs (1–100 units) for validation and testing. This process prioritizes flexibility to accommodate iterative design changes, often involving close collaboration between engineers and clients to resolve manufacturability issues early. Fabrication supports diverse board types—single/doublelayer, multilayer, flexible—and materials like FR4, Rogers, or polyimide, with quick turnaround times (3–7 days for standard designs, 24–48 hours for expedited orders). Assembly techniques blend automation and manual precision: pickandplace machines handle standard SMT components (0201–1206, 0.5mm pitch QFP), while manual soldering addresses delicate parts like 0.4mm pitch BGAs or custom components. Quality control includes detailed manual inspection, AOI for surface defects, and targeted functional testing—e.g., signal integrity checks for highspeed designs or power consumption tests for batterydriven prototypes. Valueadded services like DFM reviews optimize layouts for cost and manufacturability, while component sourcing resolves shortages through distributor networks or clientsupplied parts (CSP). Prototype PCB assembly is critical for startups and R&D teams, enabling rapid design iteration, risk mitigation, and compliance with initial testing requirements before mass production.