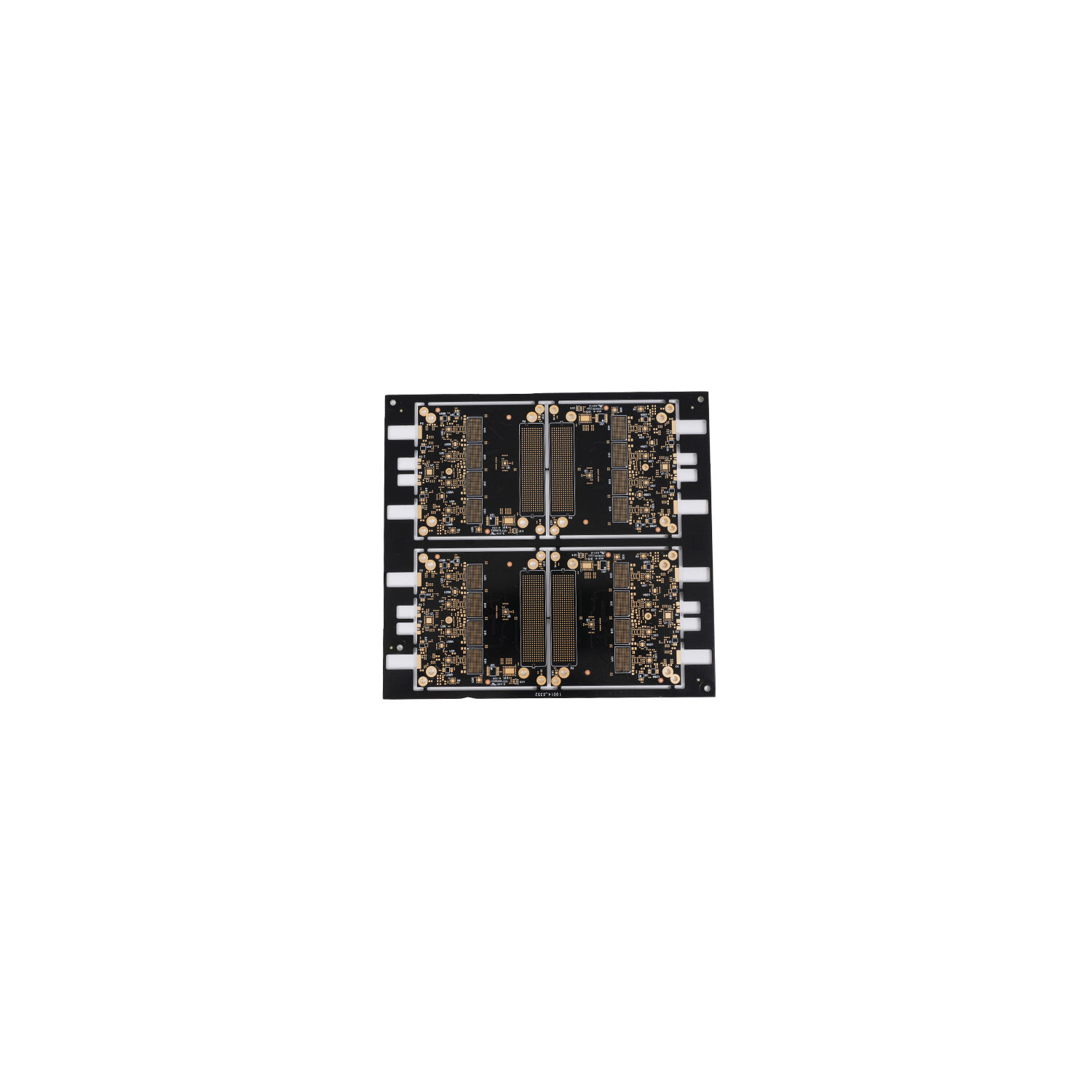

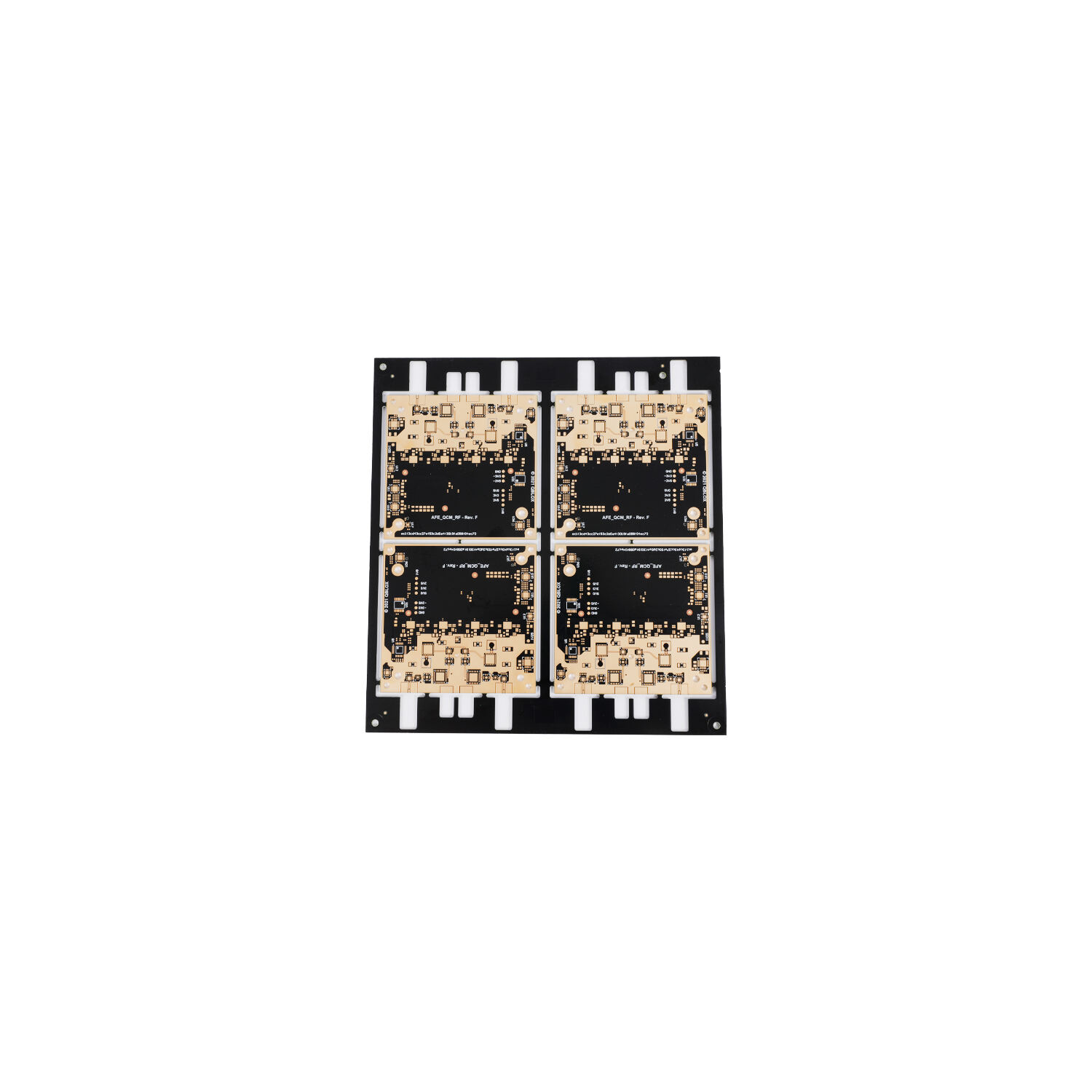

A PCB assembly manufacturer is a technical partner offering endtoend solutions, from component sourcing to final testing, with capabilities spanning prototype to highvolume production. These manufacturers operate advanced facilities equipped with SMT lines (handling 01005–1.2mm pitch components), THT wave soldering stations, and mixedtechnology lines for hybrid designs. Core competencies include material expertise—FR4, metalcore, flexible polyimide—and compliance with IPCA610 Class 2/3, ISO 9001, and industryspecific standards (IATF 16949 for automotive, ISO 13485 for medical). Supply chain management ensures component authenticity and availability, with strategies like dual sourcing and JIT inventory reducing lead times by 20–30%. Quality assurance features automated inspection (AOI, 3D Xray), functional testing (ICT/FCT), and environmental stress screening (thermal cycling, vibration). Additional services—box build assembly, conformal coating, logistics—make them ideal for complex projects, while design support (DFM/DFT reviews) minimizes production risks and costs.